Hydraulic Pumps

Hydraulic pumps are one of the necessary parts of a hydraulic system. That’s why its maintenance becomes very important day by day in order to reduce the breakdown and increase its and hydraulic system’s lifetime. 80% of the widespread breakdown is because of improper working conditions and poor maintenance.

With technology, while their efficiency has been increasing, their lifetime has been decreasing. Knowledge about hydraulic systems, experience, choices ( oil, usage or lack of filter) of end user really affects the lifetime of the hydraulic pumps from the moment of commissioning till failure. Hydraulic pumps never break down all of a sudden but they usually come through with overheat, ripple pressure, loss of flow etc. There are some simple rules to avoid such failures:

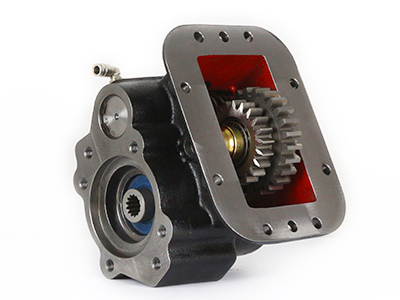

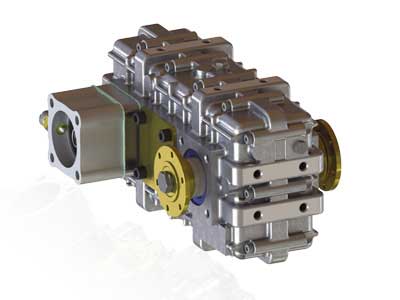

- In a hydraulic system, all pieces of equipment should be harmonious. (Cylinder, pump, PTO, valve, limitation valve, oil tank, hoses, fittings, etc.)

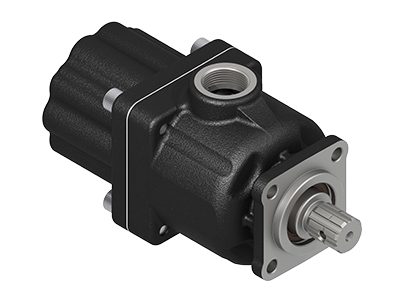

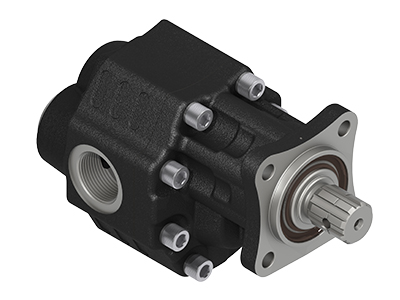

- Choose the right pump model (gear pump, piston pump, bent axis pump) with right performance values (pressure and flow) according to the purpose of a superstructure of the vehicle.

- Determine adequate connection flange type. (UNI, ISO, SAE, Shaft, etc.)

- Rotation of the pump should be determined according to rotation of drive components such as PTO and electric motor.

- All hoses and fittings sizes in a hydraulic system should be the same as inlet and outlet fittings stated in the pump catalogue. Even when the pump inlet fitting is appropriate, there must not be any contraction on other passages along the feed line below the diameters indicated on the catalogue.

- Care must be exercized to make sure that there is no strain when the pump is mounted on the drive components (i.e. electric motor, PTO, etc.), and that the nuts are fastened fully with balance and the hose is connected in an elastic and flexible position.