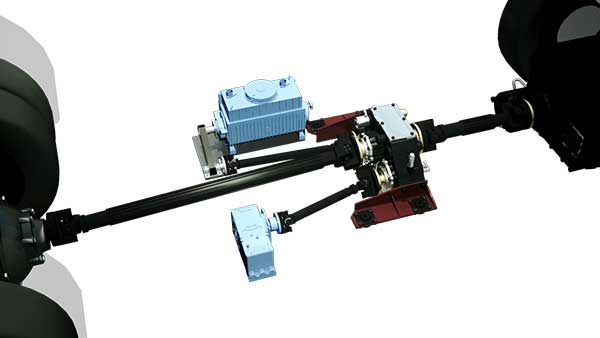

Power Take-Off - PTO

Power Take-Off - PTO

Power Take-Off (PTO) is a mechanical device which is designed for transmitting power from transmission to hydraulic pump or compressor.

Parameters characterizing PTOs: torque, ratio, rotation, mounting side and output type from PTO to pump.

PTO Selection

Gearbox Type

When selecting the right PTO to use, it is essential to define the type of the main transmission correctly. For that purpose, you will find an aluminum plate that contains all important parameters on the main transmission . According to these details, the correct PTO can be selected.

Required parameters:

- Manufacturer's name, gearbox brand

- Type,

- First gear ratio (if available)

Mounting Side

This defines the input for PTO connection.

If more than one input is available, you must select the smaller overall size (to mount PTO easily). More than one input can be used at the same time, but the current power generated in the transmission must be evaluated. In case of different PTO applications, consider contacting our technical department.

If more than one input is available, you must select the smaller overall size (to mount PTO easily). More than one input can be used at the same time, but the current power generated in the transmission must be evaluated. In case of different PTO applications, consider contacting our technical department.

Rotation

Rotation is the key factor for the right choice of pumps or other mechanical devices in which rotation direction must be uniform with the PTO.

Warning! The PTO rotation is defined when facing the PTO output. As a result, the pump rotation would be the opposite.

Warning! The PTO rotation is defined when facing the PTO output. As a result, the pump rotation would be the opposite.

Gear Position

This is one of the important details to check whether the power take-off is correctly selected. The position of the gear must be compared to the center line of the PTO output and the motion vector of the vehicle. The position is defined from the front when facing the output.

Rotation Speed

All speeds shown in the catalogue are calculated by taking into account the rated motor speed of 1000 rpm. Some transmissions are driven by a number of speed levels selected by the gear shift lever. You can find the current speeds of each PTO in the relevant catalogue.

Output Torque & Power Calculation

The following formula is used to calculate the power (kW) for the equipment to be attached.

kW = T x RPM ÷ 9550

Torque:

T = kW x 9550 ÷ RPM

Pump Input Power:

kW = P (bar) x Q (l/min) ÷ 600

Approximate engine rotation during operation:

The speed is stated as the percentage of PTO speed in regards to the engine speed. For instance, at pump speed of 1000 rpm and engine speed of 1500 rpm, the PTO rotation would be approximately two-thirds or 67%.

Equipment speed ÷ Desired Engine Speed = PTO Speed (% of the engine)

1000 ÷ 1500 = 0.666 (67%)

Intermittent Torque Requirement of Drive Components:

The following formula applies:

(kW x 9550) ÷ RPM* = N.m

T = N.m (Intermittent)

* PTO speed (rpm)

The torque value at the output of the power take-off depends on the structural parameters. During selection, the torque value must be taken into account when comparing the characteristics of the transmission system. Torque values are reported as Nm. The torque value indicated is the maximum available for each output.

Warning! Always ensure that the torque absorbed in the transmission is less than the maximum permitted by the transmission itself.